Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

How can we help you?

In view of increasing demand for environment-friendly and sustainable power generation, there is a great interest in developing renewable energy sources in an economically viable manner. Among the various renewable energy sources, solar energy is the most important and also the most widely studied.

In India, the National Solar Mission (NSM) programme under the Ministry of New and Renewable Energy (MNRE) is continuously engaged in increasing the share of solar energy in various applications like power production, industrial/domestic heating and process/building cooling.

The most common and easy way of using solar energy is the photovoltaic conversion method. In this method, the interaction between the incoming solar radiation and the silicon material of the photovoltaic module results in electricity generation.

Dry vacuum pumps are a good choice for various production processes involved in the photovoltaic industry. Some of the major processes where use of Dry screw vacuum pumps are being analyzed worldwide include:

The Solar PV industry owes its growth to the developments in the semiconductor industry. Solar PV has branched into the traditional crystalline-Si based and thin-film technologies (a/µ-Si, CdTe, and CIGS) that promise a bright future. These technologies comprise a vast array of differing processes for producing solar modules using complex machinery of which vacuum pumps are an integral part [1].

The role of Vacuum pump in individual sub processes is given below.

rrespective of monocrystal pulling or polycrystal casting process, the vacuum pump in silicon production is subjected to a large amount of reactive SiO dust. The solar cells fabricated on monocrystalline wafers provide better efficiency than the polycrystalline-based wafer. Dopants are added during the ingot growth process. Hence, this process requires a vacuum pump that works reliably well in the highly by-product generated process.

Screw vacuum pump can be used in the production of single crystal, polycrystalline and amorphous silicon. According to the size and principle of the crystallizer, the combined vacuum system of screw vacuum pump and Roots vacuum pump can be used, which greatly increases the pumping speed in the limit pressure range. Vacuum pumps have different design sizes and can reach the limit pressure of 0.01 to 0.3 mbar, providing seven standard pumping speeds (70 to 630 cubic meters per hour). When combined with Roots pump, the pumping speed can reach 4000 cubic meters or more per hour [2].

After the wafers are developed, the next process involves the fabrication of solar cells on these wafers. The various processes involved like doping and diffusion, etching, plasma enhanced chemical vapor deposition (PECVD) and physical vapor deposition (PVD). All these processes result in highly corrosive and massive dust generation. The unique capability of corrosion resistance and handling dust make the dry screw vacuum pump a one stop solution for effectively fabricating the solar cells.

The assembly of wafers with the solar cells on it are soldered together using metal connectors. The panels are made when these cells are arranged in a matrix-like structure. After arranging in the matrix-like structure they are electrically connected and encapsulated to protect from conditions like rain, snow, hailstorm etc. The encapsulation is developed by processing ethylene vinyl acetate (EVA) at high temperature in a vacuum chamber. The vacuum pump should be able to handle this EVA material. So the right choice of vacuum pump which can handle this effect and also consume less power is of vital importance [3].

Everest Vacuum, a brand of Everest Blower Systems Private Limited brings to its customers, hybrid combined variable pitch Dry Screw Vacuum Pumps (Superscrew ESPH series). These are widely used in chemical, pharmaceutical, petrochemical, food processing, plastics, CD-DVD manufacturing, thin-film & wiped film evaporation, solar PV and many other applications which require a clean and stable vacuum in general and as a central vacuum facility.

Everest Vacuum Pumping Systems are noted for their dependability and unique design, as well as their unmatched quality, value and performance. The advanced screw design results in lower energy consumption compared to standard screw design. This also results in lower heat generation during the compression of the gases/vapours. There is No Oil / No Water in contact with the process vapours, therefore they are considered as extremely environment-friendly. As these pumps are completely dry, the process vapour can pass through the pump without any contamination and be collected at the discharge of the system by a vent condenser. This offers the customer a very efficient vapour recovery management system and an environment friendly vacuum ecosystem [4].

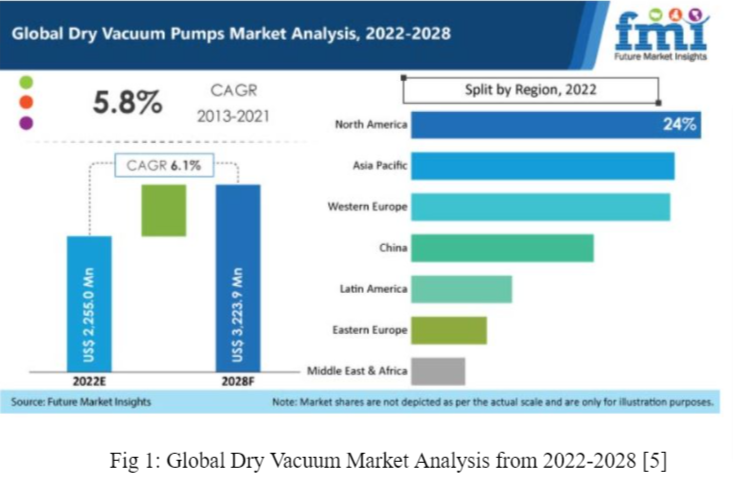

Demand for dry vacuum pumps accounted for around 3.2% share of the global industrial pumps market in 2021. The global dry vacuum pumps market witnessed a growth rate of 5.8% over the period of 2013 to 2021. Expanding at a CAGR of 6.1%, the global dry vacuum pumps market is projected to increase from a valuation of US$ 2.25 Bn in 2022 to US$ 3.22 Bn by 2028 [5].

Everest Vacuum has been providing Technical and R&D solutions for various process industries over the last 15 years. We have provided customized vacuum systems to many reputed organizations in India and overseas. We believe in empowering our customers with the best possible customized vacuum system for eco-friendly overall development.

Dr V Ravindra is a Mechanical Engineer who has done his PhD from Indian Institute of Technology, Kharagpur. He is working as R&D Manager at Everest Vacuum and he is involved in designing modern vacuum systems for process applications based on customer requirements. He is also developing training modules related to Vacuum Technology and process applications.