Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

How can we help you?

Many times when I start my discussion with the process plant engineers their first question is why does my Vacuum pump fail? Do I continue to replace or repair the Vacuum pump or do I make a shift to some new technology of the Vacuum Pump? If I make this switch to a new technology Vacuum Pump, how will it affect my cost of Utilities and what surety that I have that this new technology will work better as compared to the existing one? These questions are asked more often than not.

In our recent experience, we have seen more and more explorations and experimentation by process companies with different Vacuum technologies on existing processes. The conventional wet vacuum pumping is being replaced by the relatively newer dry vacuum pumping using pumps such as Roots Booster Vacuum Pump, Dry Screw Vacuum Pump, and Claw Vacuum pumps. The typical wet vacuum pumps are Water jet Ejector Vacuum Pump, Steam Jet Ejector Vacuum pump, Liquid Ring Vacuum Pumps, Rotary/Reciprocating Oil Ring Vacuum Pump, etc. This switch has yielded in many cases success stories and in some cases unexpected challenges, we still believe that such experimentation & trials are not only healthy to challenge the status quo but also necessary to push the boundaries of vacuum application to drive innovation and cost-saving in different industries and processes.

Vacuum Specialist when choosing the right Vacuum pumps & Systems, typically consider the following parameters to make the best choice:

As you see, the list of the above dynamic parameters goes beyond the mere vacuum pump selections based on the level of vacuum & capacity rather a more holistic approach needs to be taken as multiple vacuum pump technologies can be a possible solution interim solution but the most cost-efficient long term solution can be identified by making a product selection matrix which will weigh in all parameters and help us in making a more holistic decision considering the Total Cost of Ownership over the product life cycle. The parameters that constitute of this matrix are as follows:

As you see that the decision to make the right selection involves so many dynamic parameters, however, to simplify & summarise this decision-making process we shall be discussing real case scenarios using case studies. To protect the company’s proprietary information we shall not be using any company’s specific name or its extensive process details. Most cases will be generalized enough so that the science can be applied across multiple applications.

Distillation at reduced pressures is a widely used process in the Chemical & Pharmaceutical Industry, especially used in extraction/purification of Essential Oils, Deodorisation of Vanaspati / Vegetable Oils, and Purification & Drying of Chemicals. The advantages of the low-pressure distillation process over Atmospheric pressure distillation are as under :

In order to ensure satisfactory operation of the distillation process, it is essential that suitable vacuum pumps are used. While there is no single perfect pump, the ideal characteristic of the vacuum pump required for the distillation process are :

No single Vacuum Pump can meet all the above criteria completely & so it becomes very important to make the selection based on the matrix as stated above.Some of the widely used pumps for distillation are described below along with their limitations:

These pumps use water and sometimes oil as the pumping medium. For this reason with ring-type pumps, the ultimate vacuum achieved gets limited to the vapor pressure of the pump fluid at the working temperature. Owing to the above, even an efficient double stage Water Ring Pump would stall at around 30 Torr abs.(730 mm Hg), since the vapor pressure of water at 30DegC is about 30 Torr. They have further disadvantages of being highly energy inefficient because most of the power is lost in friction losses of moving the pump fluid inside the pump. This restricts the water ring (or oil ring) pump to relatively modest volumetric pumping capacities. Water ring pumps are widely used in the food processing and pharmaceutical industry since any other sealing fluid contamination is not acceptable. This restricts the process capabilities as working vacuum & speeds get restricted. Another disadvantage of ring pumps is that the working fluid often has to be treated before it can be discharged or reused as it contains the carry-over of condensed product.

Steam ejectors can produce low pressures (when used in multiple stages with suitable condensers) and have very high volumetric speeds. However, they require the maintenance of a complete steam generation facility confirming to IBAR regulations and inspection. They are generally not available as stand-alone installations but can be found where process steam is easily available. Relatively large barometric condensers are required to handle the ejector steam. For obvious reasons, a large amount of soft-demineralized water is required which is an additional recurring expense. In addition, the cost of treatment of water/effluent which is a mixture of the process vapor and water also adds to the cost of the utilities.

These types of pumps have high power to capacity ratios and are therefore not available in large volumetric capacities. They are effective for pumping non-condensable loads but have a limitation of not being able to pump large & regular quantities of water vapor (and other vapors) released in low-pressure vacuum processes. Various precautions have to be taken if they are used for food-grade applications to avoid contamination of process material by the pump oil or backstreaming of oil vapors.

These types of vacuum pumps have high volumetric efficiency, are 100% dry, and have the capability of allowing the process vapors to pass through them and get collected at the discharge by using a post condenser thus limiting the environmental impact. Since they are also 100% and require no sealing fluid such as Oil/Water the chances of contamination is also greatly reduced. The limitation in these pumps is of a warm-up cycle to ensure the geometry of the screw grows under heat to close off the tolerances to prevent slip losses during operation & ensure that the pump internals is HOT enough to prevent vapor condensation within the pump. The shutdown cycle is also important and a solvent flush &/or a purge cycle operation is done isolating the pump from the process so as to ensure no internal condensation occurs after the pump shuts down and cools down.

Mechanical Vacuum Booster is a Dry pump that meets most of the ideal pump requirements. It works on the positive displacement principle. As its name suggests, it is used to boost the performance of water ring/oil ring/ rotating vane/piston and in some cases even steam ejector pumps. It is used in conjunction with any one of the above mentioned pumps, to overcome their limitations. Mechanical Vacuum Boosters pumps offer very desirable characteristics, making them the most cost-effective & power-efficient alternative. The major advantages are :

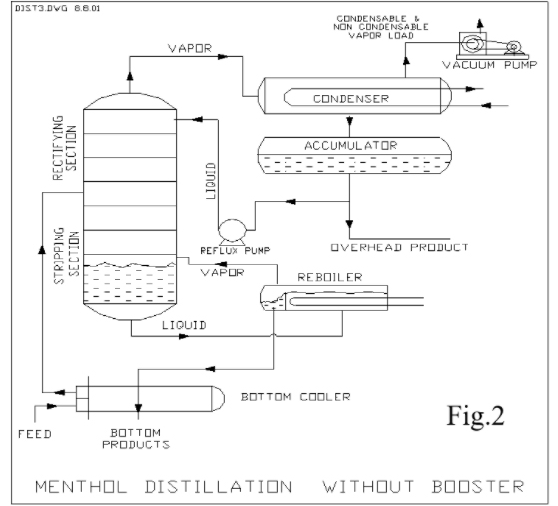

An existing menthol distillation unit used 2 x 10 HP Piston Type Vacuum Pumps (Ingersoll Rand make) and was having problems in achieving & maintaining adequate vacuum. This resulted in poor quality products and low production rates. The distillation column had imported packing material yet the desired final product quality & production rates could not be achieved, since inadequate vacuum levels were achieved. (ref. Fig. 2)